Project Summary:

Expanding industrial operations often requires innovative solutions to meet operational demands and environmental regulations. This case study delves into the development of an advanced chemical storage facility that not only accommodated the client’s need for large-volume storage but also addressed environmental concerns in a sensitive area.

Located within an existing industrial site adjacent to a sensitive environmental area, the client sought to construct two new large-volume chemical storage tanks totaling over 100ML (26.5 million gallons). Given the shallow water table and stringent monitoring by the Environmental Protection Agency (EPA), the project required meticulous design, installation, and operational practices to ensure compliance with the best containment standards.

Solution:

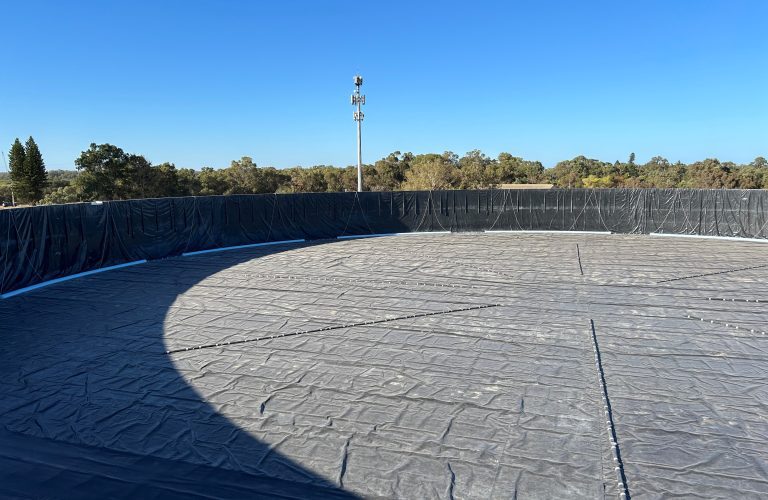

To meet the client’s capacity and environmental protection requirements, a triple-liner system with integral leak detection and removal between primary and secondary geomembrane liners was implemented. The primary and secondary liners were composed of Enviro Liner® 6040, and the tertiary liner was composed of a GCL. The liner panels were also factory prefabricated to ensure precise installation and minimize on-site construction time.

Multiple geosynthetic layers manufactured and supplied by Layfield, including Enviro Liner®, Geovolt® 8oz, and conductive HydraNet™ Geocomposite, were chosen for their superior performance in advanced chemical storage, containing hazardous chemicals while meeting environmental standards.

Implementation and Fabrication: The construction of the storage tanks involved several key steps to ensure the integrity and stability of the liner system. Earthed Leak Location Surveys (ELLS) were conducted on both the secondary and primary liners, providing additional assurance of containment effectiveness. Permanent ballast was installed on walls and floors to maintain the stability of the geosynthetic liner system under varying conditions.

Long-Term Monitoring and Maintenance: A comprehensive monitoring plan was implemented to ensure the storage facility’s ongoing performance. Twenty Enviro Liner® test strips were installed in each tank, with annual condition testing planned over the 20-year asset life. This proactive approach to maintenance aims to detect any potential issues early, allowing for timely remediation and ensuring the continued safety and compliance of the facility.

Conclusion:

The successful completion of the chemical storage facility demonstrates advanced containment solutions’ efficacy in meeting operational and environmental objectives. By incorporating triple-liner systems, leak detection mechanisms, and long-term monitoring plans, the project not only addresses the immediate needs of the client but also upholds the highest standards of environmental stewardship in sensitive areas.