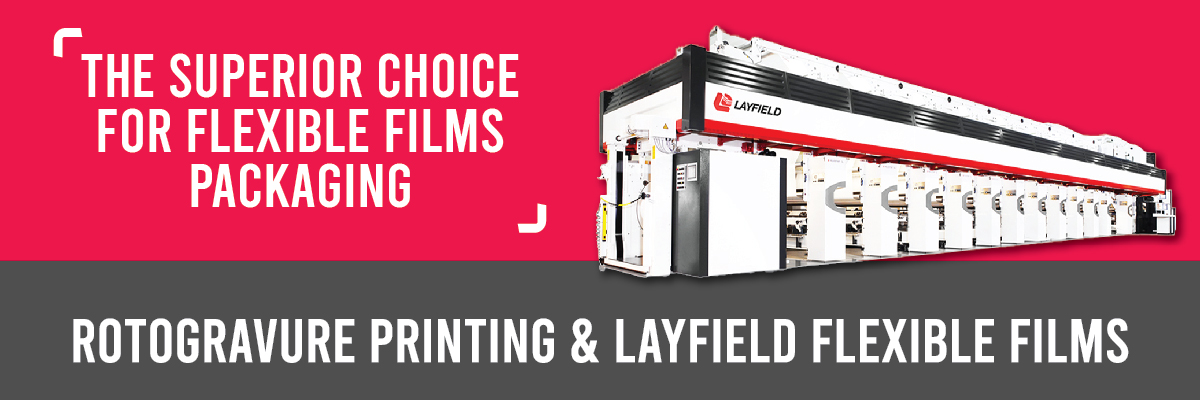

In the competitive landscape of flexible films packaging, choosing the right printing technology can significantly impact the quality, efficiency, and overall success of your packaging solutions. Among the various printing methods available, rotogravure printing stands out as the superior choice, especially for high-volume, high-quality packaging needs. Layfield Flexible Films, a leader in the industry, leverages this advanced technology to deliver unmatched results for their clients.

Understanding Rotogravure Printing

Rotogravure printing, commonly known as gravure printing, is a high-quality, high-speed printing process used predominantly for large-scale production runs. This technique involves engraving the image onto a rotary printing cylinder. The engraved cells hold the ink, which is transferred directly onto the substrate, in this case, flexible films. This direct transfer ensures consistent, high-resolution images with exceptional detail and vibrant colors.

“…rotogravure printing stands out as the superior choice, especially for high-volume, high-quality packaging needs.“

Advantages of Rotogravure Printing for Flexible Films

- Exceptional Print Quality: One of the primary reasons rotogravure printing is favored for flexible films is its ability to produce exceptionally high-quality prints. The process allows for fine details, smooth gradations, and rich, vibrant colors, making it ideal for complex designs and images. Rotogravure printing can deliver up to 12 colors, enabling stunning, intricate designs that capture attention and enhance the brand appeal.

- High-Speed Production: Rotogravure printing is known for its efficiency in high-speed production environments. This makes it particularly advantageous for large-scale packaging operations where time and efficiency are crucial.

- Consistent Results: The durability of the engraved cylinders used in rotogravure printing ensures that the quality of the print remains consistent throughout the entire production run. This consistency is essential for maintaining brand integrity and meeting consumer expectations.

- Cost-Effective for Large Runs: While the initial setup costs for rotogravure printing can be higher than other methods, such as flexographic or digital printing, it becomes highly cost-effective for large production runs. The long-lasting cylinders and fast production speeds reduce overall costs per unit as the volume increases.

- Versatility: Rotogravure printing is highly versatile and capable of printing on a variety of substrates, including different types of flexible films. This versatility allows for the creation of diverse packaging solutions tailored to specific product needs. Additionally, rotogravure printing offers the ability to incorporate special effects such as matte finishes combined with spot gloss effects, enhancing the visual and tactile appeal of the packaging.

Layfield Flexible Films: Leveraging Rotogravure Printing

Layfield Flexible Films is at the forefront of the packaging industry, utilizing rotogravure printing technology to deliver superior packaging solutions. Their commitment to quality, innovation, and customer satisfaction is evident in the advantages they provide through this advanced printing technique.

- State-of-the-Art Equipment: Layfield Flexible Films employs a state-of-the-art rotogravure printing press, ensuring that every print run meets the highest standards of quality and precision. Their investment in the latest technology translates to better outcomes for their clients.

- Expertise and Experience: With years of experience in the packaging industry, Layfield’s team of experts understand the intricacies of rotogravure printing. This expertise allows them to optimize the printing process, ensuring efficient production and outstanding results.

- Custom Solutions: Layfield Flexible Films offers custom printing solutions tailored to each client’s unique needs. Whether creating eye-catching designs for retail packaging or ensuring functional packaging for industrial applications, Layfield’s rotogravure printing capabilities are up to the task. The ability to use up to 12 colors and incorporate effects like matte finishes with spot gloss highlights allows for truly customized and visually striking packaging.

- Sustainability Initiatives: Layfield is committed to sustainability and uses environmentally responsible practices in their production processes. Rotogravure printing, with its efficient ink usage and minimal waste, aligns with Layfield’s sustainability goals, helping clients reduce their environmental footprint.

- Comprehensive Support: Beyond just printing, Layfield Flexible Films provides comprehensive support, from design consultation to final production. Their end-to-end service ensures that clients receive a seamless and satisfactory experience.

Conclusion

In the realm of flexible films packaging, rotogravure printing emerges as the best technology due to its superior print quality, high-speed production capabilities, consistent results, cost-effectiveness for large runs, and versatility. The ability to print up to 12 colors and incorporate special effects like matte finishes with spot gloss highlights further enhances its appeal. Layfield Flexible Films harnesses the power of this technology, backed by its state-of-the-art equipment, industry expertise, commitment to sustainability, and comprehensive customer support.

For businesses looking to elevate their packaging solutions, Layfield Flexible Films and their advanced rotogravure printing technology offer an unbeatable combination.

Related Articles

View All News