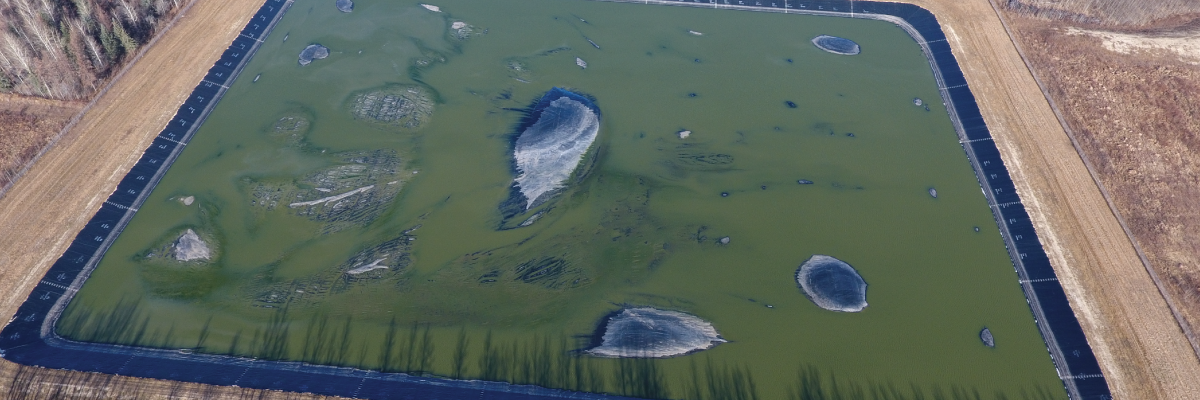

Layfield Geosynthetics is a trusted problem-solving partner in the geomembrane community. Clients rely on us when they encounter issues such as geomembrane liners floating near or above the surface of containment ponds, commonly known as “Whales” or “Hippos.” These occurrences are often a result of water or gas collecting under the geomembrane, causing it to rise. Often, this isn’t necessarily due to a leak but to groundwater or soil gas issues that may not have been adequately addressed during design or installation.

Depending on the root cause of the issue, several methods exist to address this problem. However, in this technote, we will focus on preventing the problem since fixing it later can be complicated and costly.

A comprehensive geotechnical report can help identify potential issues like proximity to the water table or the presence of organic materials generating soil gases. If groundwater or soil gases are present, we can incorporate methods to release them from beneath the geomembrane, preventing liner lifting. A practical method is to place a geonet or geocomposite under the liner, providing a “Path of least resistance” for the soil gas or groundwater pressure. A geonet is a 3-dimensional polyethylene mesh made to allow water or gas to pass through with little resistance. A geocomposite is a geonet laminated to a non-woven geotextile on either one or both sides. Layfield manufactures and distributes geonet and geocomposite, which we market under the tradename HydraNet®.

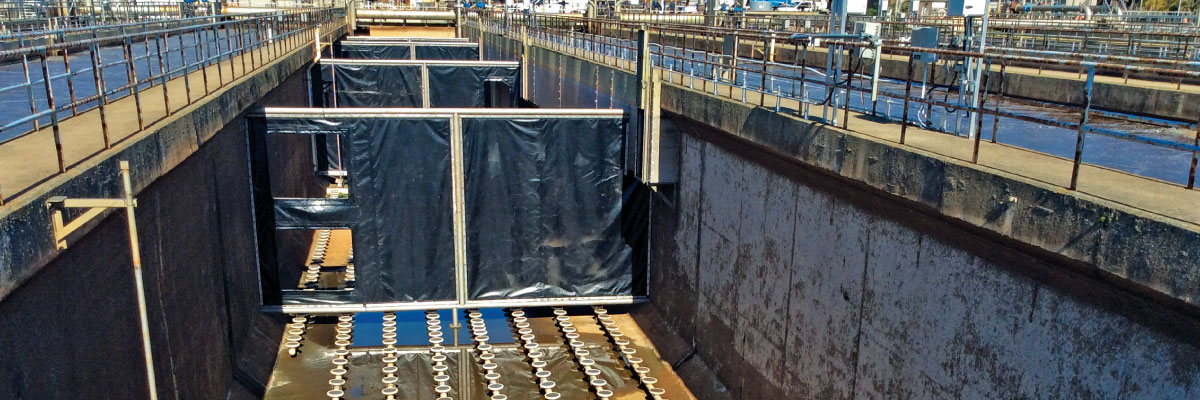

HydraNet® is placed over the prepared subgrade, and then the geomembrane is placed directly on top. Using a geonet or geocomposite depends on factors like subgrade conditions, geomembrane selection, and service conditions. Gas can still have trouble moving through a geonet full of water (groundwater); therefore, whales can still accumulate under a liner system if groundwater issues have not been addressed. Actively pumping the groundwater to eliminate the groundwater intrusion into the geocomposite layer will then allow soil gases to be vented thus removing the potential for “Whales”.

If the HydraNet® is required to move soil gases out from under the liner, it is run along the base and up the side of the slopes to an outlet where the gases can vent off. If the intent is to prevent water buildup, then the HydraNet® is placed to help move the water to a low spot or sump below the liner where it can be effectively managed. HydraNet® can be placed to cover the entire area or only a small portion, depending on the amount of water or soil gas present.

The use of HydraNet® is not limited to mitigating water or gas pressure buildup beneath a geomembrane. HydraNet® can also provide ongoing leak detection, and when placed under buildings, it can move radon or other on-site contaminants. It can also act as a highly effective cushioning layer on sites with poor subgrades.

Navigating the geomembrane design process requires careful consideration of various factors. With over 40 years of experience, Layfield offers guidance as a manufacturer, distributor, and installer. We’re committed to providing objective recommendations on the best geosynthetic materials for each application, helping you reduce costs, expedite construction safely, and minimize environmental impact. Contact us today to discover how we can support your projects.

Related Articles

View All News