Written By Brian Fraser, Vice President

Layfield Geosynthetics | July 2024

This technote discusses PFAS substances and the use of geomembranes to contain them. It also discusses geomembrane formulations and the importance of confirming your geomembrane selection when dealing with PFAS synthetic chemicals.

What are PFAS Substances?

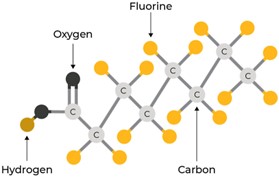

Per- and polyfluoroalkyl substances (PFAS) are a large, complex group of synthetic chemicals that have been used in consumer products worldwide since the 1950s. They are ingredients in various everyday products. For example, PFAS are used to keep food from sticking to packaging or cookware, make clothes and carpets resistant to stains, and are used in some firefighting foams. PFAS molecules have a chain of linked carbon and fluorine atoms. Because the carbon-fluorine bond is one of the strongest, these chemicals do not degrade easily in the environment.

Scientific studies have shown that exposure to some PFAS in the environment may be linked to harmful health effects in humans and animals. Experts estimate that every year, 16,500 pounds of PFAS from discarded household goods, industrial waste, and more end up in landfills.

The major sources of PFAS contamination are in drinking water, groundwater, soils, and air, include:

- Fire training/fire response sites.

- Industrial sites.

- Landfills.

- Wastewater treatment plants and resulting biosolids.

Treatment & Removal

Several thermal technologies are currently used to treat and destroy PFAS, including high-temperature incineration, thermal conduction heating, infrared heating, and thermal reactivation treatment. In drinking water, specific activated carbon filters, ion exchange treatment, and reverse osmosis membranes have been shown to be effective at removing PFAS from water supplies.

Industry Performance Testing

Various industry tests of geomembranes’ resistance to PFAS have been performed over the past few years, and additional testing is currently being conducted to better determine chemical resistance and performance suitability. This includes a 3-year testing program underway at Queen’s University in Kingston, Ontario, Canada, where a number of thermoplastic geomembranes are undergoing chemical immersion testing for PFAS in landfill leachate. The materials are primarily being evaluated for vapor diffusion and sorption rates and retained tensile strengths. This testing is being conducted with different concentrations of PFAS, including at 1 ppm and 20 ppm and temperatures at 23°C, 35°C and 50°C (73°F, 95°F, 122°F). Initial test results have shown very low PFAS diffusion rates through several different geomembrane products, making most products highly effective diffusion barriers. The Fabricated Geomembrane Institute (FGI) is also a good source of industry information on PFAS testing, including a technote and an informative online seminar recently conducted by Dr. Kerry Rowe of Queen’s University.

PFAS Free Geomembranes

Increasingly, municipalities and private water operators are requesting verification that geomembrane liners and floating covers being used in the treatment and storage of potable water, wastewater, and municipal solid waste contain no levels of PFAS. Most standard HDPE and LLDPE geomembrane formulations contain approximately 97 to 98% polyethylene, 2 to 3% carbon black, and less than 0.1% process aid, which is added to improve processability and reduce melt fracture. Process aid is a fluoropolymer which falls under the category of PFAS substances. Today, many resin and carbon black manufacturers can provide certified PFAS-free products. Newer alternative PFAS-free process aids are also becoming available within the industry. This combination has allowed manufacturers of polyethylene geomembranes (HDPE and LLDPE) to increasingly provide new PFAS-free geomembrane products.

In February 2023, the European Chemical Agency proposed a ban on PFAS, including process aids containing PFAS. On November 22, 2023, The European Chemical Agency issued a testing report on PVC and PVC additives, identifying serious health and environmental concerns arising from PVC additives, including plasticizers and heat stabilizers. Owners, operators, and engineers should request written confirmation from manufacturers, regardless of the polymer type, to ensure their products are PFAS-free.

What Next

The geomembrane industry, including both resin and additive suppliers and geomembrane converters, are actively testing and reformulating geomembranes to ensure the supply of PFAS-free products. Ongoing performance testing is being conducted to better understand geomembranes’ chemical resistance and performance properties for PFAS containment applications. It is expected that the government will increase levels of funding and environmental regulations regarding the detection, monitoring, and treatment of PFAS. It is important to stay updated on PFAS-related market updates by government and industry.

References

- US EPA Per and Polyfluoroalkyl Substances – https://www.epa.gov/pfas

- Fabricated Geomembrane Institute – Webinar, November 10, 2020, Strengths and Uncertainties regarding PFAS by Modern Liner Systems, https://www.fabricatedgeomembrane.com/resources/webinar-archives

- Science Direct, Diffusion and partitioning of different PFAS compounds through thermoplastic polyurethane and three different PVC-EIA liners – https://www.sciencedirect.com/science/article/abs/pii/S0048969723028504#:~:text=Significant%20diffusion%20of%20PFAS%20through,making%20them%20excellent%20diffusion%20barriers

- Geosynthetics ATA, Geomembrane resin manufactures embrace non-PFAS polymer processing aids amidst growing regulatory pressure. https://geosyntheticsmagazine.com/2023/09/21/geomembrane-resin-manufacturers-embrace-non-pfas-polymer-processing-aids-amidst-growing-regulatory-pressure/

- NIH National Institute of Environmental Health Sciences, Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS), https://www.niehs.nih.gov/health/topics/agents/pfc#:~:text=They%20are%20ingredients%20in%20various,linked%20carbon%20and%20fluorine%20atoms.

- ECHA European Chemical Agency, Investigation Report on PVC and PVC Additives https://echa.europa.eu/documents/10162/17233/rest_pvc_investigation_report_en.pdf/98134bd2-f26e-fa4f-8ae1-004d2a3a29b6?t=1701157368019

- Excelplas, Premature Failure of Geomembrane Floating Covers in Australia: Cause, Comparisons and Recommendations – https://www.excelplas.com/premature-failure-of-geomembrane-floating-covers-in-australia-causes-comparisons-and-recommendations/

Related Articles

View All News