Written By GNA Editor (Geosynthetic News Alerts) | 26th June 2023

ABSTRACT

In potable applications, some RPP installations have failed in as little as four years, while others have managed to achieve seventeen years of service. Nearly all RPP covers in Australia have failed or degraded prematurely. The majority of failures have been due to chemical attack from chlorine exposure. Systems with chloramine disinfection have been particularly affected. Other chemical attack mechanisms have been through very pure water generated by reverse osmosis desalination plants (negative or low Langelier Saturation Index water). These RPP failures have been accelerated by high UV exposure and high ambient temperatures. It is interesting to compare the performance of RPP with CSPE. The average age of CSPE floating covers at replacement in Australia is 27.25 years compared to RPP at 11.3 years. There are a number of examples of CSPE covers in Australia exceeding 35 years still in service, whereas all the remaining RPP Floating covers are showing serious signs of degradation. Thus CSPE gives 250-300% greater proven service life than fPP and RPP. PVC-EIA materials, while not used extensively in Australia at the time of writing, have also shown relatively short asset life, and this appears dependent on the formulation.

introduction

Geomembrane floating covers play a crucial role in protecting potable water reservoirs from contamination. However, in Australia, due to harsh UV and weathering effects, a concerning trend of premature failure and degradation of these covers has been observed. This article delves into the factors contributing to this issue, with a specific focus on the failure of Reinforced Polypropylene (RPP) covers and the comparison with Chlorosulfonated Polyethylene (CSPE) covers. Additionally, the article discusses the performance of Polyvinyl Chloride-Ethylene Interpolymer Alloy (PVC-EIA) materials and offers recommendations to mitigate premature failures.

Causes of Premature Failure

The primary cause of premature failure in geomembrane floating covers in Australia is chemical attack, mainly resulting from chlorine exposure and high surface temperatures. Covers employed in systems with chloramine disinfection have been particularly susceptible to degradation. Furthermore, high-purity water generated by reverse osmosis desalination plants, characterized by negative or very low Langelier Saturation Index, has also posed chemical attack challenges. Accelerating factors such as intense UV exposure and high ambient temperatures have further contributed to the premature failure of RPP covers.

Comparative Performance Analysis: Comparing the performance of RPP and CSPE covers reveals significant differences. The average age of CSPE floating covers at the time of replacement in Australia is 27.25 years, compared to 11.3 years for RPP covers. Notably, several CSPE covers in Australia have exceeded 35 years in service, while the remaining RPP floating covers exhibit serious signs of degradation. CSPE materials offer a proven service life that is 250-300% greater than that of RPP and fPP (formulated Polypropylene).

PVC-EIA Material: While PVC-EIA materials have not been extensively utilized in Australia, their performance has shown relatively short asset life, which appears to be formulation-dependent. Further investigation is warranted to explore the specific factors influencing the performance of PVC-EIA covers and potential solutions to enhance their longevity.

The selection of suitable materials is a crucial factor in ensuring the long-term durability and optimal performance of floating covers. Several challenges and considerations need to be taken into account, as the chosen materials must withstand various environmental factors and stressors, ensuring prolonged service life.

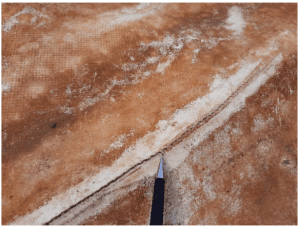

Reinforced Polypropylene (RPP) Covers: RPP covers, although widely used, demonstrate signs of fatigue and premature degradation within 10-15 years of service. Cracks often appear around folds and creases, leading to concerns about the extent of damage to the geomembrane liner material (see photo below). Factors such as prolonged UV exposure, continuous chlorine exposure in potable water disinfection, and stress concentrations at folds due to hydrostatic pressure contribute to the cracking and subsequent material failure.

Chlorosulfonated Polyethylene (CSPE) Covers: CSPE covers have a long-established track record, with over 50 years of proven performance in municipal water containment applications involving chlorine and other disinfectants. CSPE geomembrane material exhibits excellent UV resistance and is backed by a 30-year weathering warranty. Its high flexibility and stress distribution capabilities make it a reliable choice for floating covers.Fortified Geomembranes: Fortified geomembranes are products that undergo extensive dosing with stabilizers, providing enhanced heat resistance, UV stability, and chemical resistance. This fortification significantly improves the durability and longevity of the material, making it suitable for demanding applications like floating covers.

To ensure the selection of suitable materials for floating covers, site-specific conditions must be evaluated, and collaboration with material suppliers is essential. Considering long-term durability factors, such as UV exposure, chemical resistance, and flexibility, aids in making informed decisions regarding material selection. The importance of material selection in floating covers cannot be overstated. RPP covers are prone to premature degradation, while CSPE covers offer superior durability, UV resistance, and flexibility. Choosing fortified geomembranes further enhances the stability and chemical resistance of floating covers. By prioritizing appropriate materials, the longevity and performance of floating covers can be optimized, ensuring reliable and effective protection for various applications.

Recommendations

1. Chemical Resistance: Emphasize the selection of materials with superior resistance to chlorine and chloramine exposure.

2. Material Comparison: Prioritize CSPE covers due to their proven extended service life compared to RPP and PVC-EIA.

3. UV Protection: Implement UV stabilization measures in cover designs to reduce the detrimental effects of UV radiation.

4. Temperature Management: Employ strategies to mi-gate the impact of high ambient temperatures on cover degradation.

5. Long-Term Monitoring: Regular inspections, maintenance, and condition assessments can help identify degradation signs and prompt timely intervention.

6. Research and Development: Foster ongoing research and development efforts to improve the durability and chemical resistance of geomembrane materials.

Conclusions

The premature failure of geomembrane floating covers in Australia, predominantly caused by chemical attack from chlorine exposure, poses significant challenges for potable water applications. CSPE covers have demonstrated exceptional longevity compared to RPP and PVC-EIA materials. To ensure the sustained performance and extended service life of these covers, it is crucial to address chemical attack, UV exposure, and temperature-related factors while considering material selection, design improvements, and ongoing monitoring.

References and Future Reading

https://www.layfieldgroup.com/wp-content/uploads/2023/06/A-History-of-Geomembrane-Floating-Covers-in-Australia.pdf

https://www.layfieldgroup.com/wp-content/uploads/2023/03/Case-Study-Lake-Forest-Reservoir-Relining-Floating-Cover.pdf

To view the original article posted by the GNA (Geosynthetic News Alerts), click here.

Related Articles

View All News