Written By Brian Fraser, Vice President

Layfield Geosynthetics | August 2024

This technote discusses the importance and benefits of flexibility in geomembranes. It includes understanding the differences in flexibility by geomembrane polymer type and geomembrane structure, including reinforced and non-reinforced. It also discusses different test methods for determining geomembrane flexibility.

Benefits of Flexibility

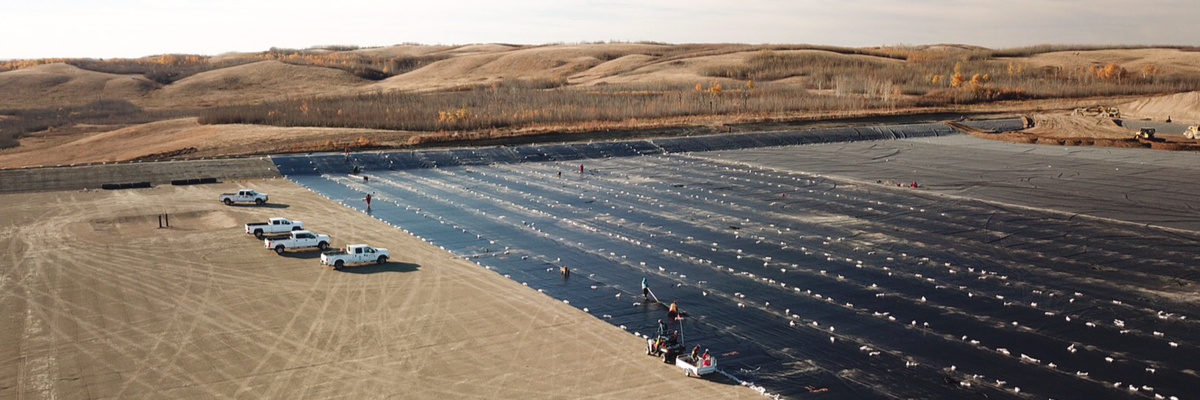

Geomembrane flexibility is important for numerous performance requirements including the ability to factory fabricate liners. Factory fabrication, also referred to as prefabrication, provides the ability to produce larger custom-size panels in the factory in a controlled environment. The fabrication process includes welding, testing, folding, and then winding of flexible geomembrane roll stocks into larger finished-size panels. The folding and winding process requires a suitably flexible material that will not be damaged due to excessive stress, strain, and compression. Prefabrication reduces the quantity of field welds and can provide better overall seam quality and reduced installation time.

Other important benefits of flexibility in geomembranes include higher yield properties, allowing the material to be folded and bent without deforming or weakening the material during installation or as part of the containment application. This can be important where geomembrane bending is required at sharp transitions of grade, e.g., tank floor-to-wall transitions, or around features, including inlet and outlet structures, pipes, columns, etc. It can be equally important when addressing wrinkles due to thermal expansion and contraction and material folds or creases associated with deployment and installation in the field.

Applications

Common applications of flexible geomembranes include prefabricated liners for stormwater runoff using underground stormwater tanks for storage and retention, water and wastewater ponds, prefabricated above-ground storage tanks, landfill caps, anaerobic digester covers, and municipal floating covers to protect potable water. In these applications, the geomembrane material requires higher tensile elongation and multiaxial properties. In comparison, HDPE geomembrane, which provides very good chemical and UV resistance properties, is a more crystalline, stiffer material with lower yield elongation properties. HDPE is unsuitable for prefabrication and should only be welded in the field with good subgrade preparation and compaction conditions.

Elastic versus Plastic Geomembranes

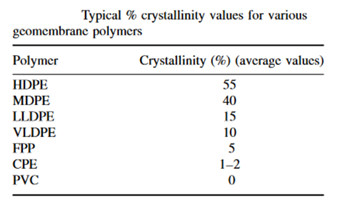

Molecular weight, density, and crystallinity in polyolefin-type geomembranes, including HDPE, MDPE, and LLDPE materials, are important factors in flexibility. HDPE geomembranes have a higher density, molecular weight, and crystallinity, providing good overall chemical resistance but increasing rigidity. In contrast, non-reinforced PVC, PVC EIA’s, and fRPP liners are more amorphous in their molecular structure with much lower crystallinity. As a result, they demonstrate much better flexibility. However, there are often essential performance tradeoffs associated with flexibility with standard PVC and fRPP geomembranes, including less chemical and UV resistance unless specially formulated.

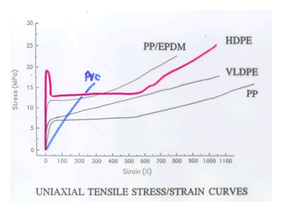

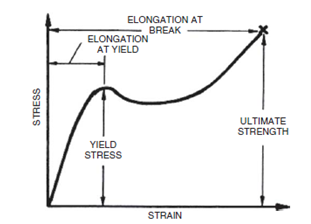

Yield elongation is also a good method of measuring geomembrane elongation and flexibility. Yield is defined as the onset of plastic deformation in the polymer under an applied load. The yield properties depend on the polymer crystallinity and the polymer morphology. Plastic deformation is the deformation that remains after a load is removed from a polymer sample. It is called permanent deformation. Geomembranes that have exceeded their yield elongation properties are determined to be permanently damaged. Typical industry HDPE geomembranes have a yield point of approximately 12%. LLDPE and polypropylene (PP) have higher yield points, which can be more difficult to distinguish on a stress-strain curve. Both demonstrate higher yield elongation properties compared to HDPE. PVC, which is highly amorphous in its structure, shows no obvious yield point in the stress-strain curve. It is also important to note that higher temperatures or losses with geomembrane oxidizers or plasticizers can further impact yield points in materials.

Flexibility Testing

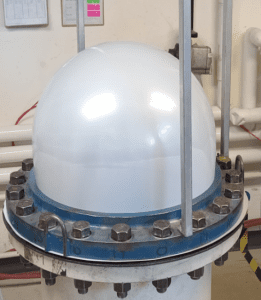

There are a number of test methods directly and indirectly related to measuring flexibility in geomembranes. For unreinforced polyolefin geomembranes, tensile elongation and multiaxial axial testing are commonly used to determine the material’s elongation at yield and elastic properties. Various non-reinforced flexible geomembranes, including LLDPE and PVC, typically demonstrate very good multiaxial properties. Multiaxial properties are the geomembrane’s ability to stretch or elongate in the out-of-plane direction. This can be an important requirement to address soil deformation on projects with inconsistent or poorly compacted subgrades. It is also important when confronted with ballooning of liners due to organic gases or air trapped under the liner. Flexible geomembranes with higher elongation properties can also provide better-truncated cone puncture properties, allowing the geomembrane to stretch and elongate over minor imperfections, including soil clumps and stones in the subgrade. Axisymmetric tension strain testing, or multiaxial strain testing, determines the perpendicular or out-of-plane tensile forces of geomembranes often associated with differential settlement problems. Multiaxial testing is typically performed in accordance with the ASTM D5617 standard. Materials with higher yield elongation properties normally demonstrate higher multiaxial and flexibility properties. For testing tensile properties, ASTM D6693 is commonly used for polyolefin products to measure yield break strength and break elongation.

ASTM D1388-14 is another suitable test method for testing stiffness in reinforced and non-reinforced geomembranes. This test method measures stiffness properties in fabrics. The testing scope includes measuring the specific bending points of materials and then calculating their flexural rigidity. The Fabricated Geomembrane Institute (FGI) is currently conducting further research and testing of various geomembranes in accordance with ASTMD1388. Below are three standard test methods to help measure flexibility in geomembranes.

- ASTM D6693-20 Standard Test Method for Determining Tensile Properties of Non-reinforced Polyethylene and Non-reinforced Flexible Polypropylene Geomembranes

- ASTM D5617-23 Standard Test Method for Multiaxial Tension Test for Geosynthetics

- ASTM D1388-14 Standard Test Method for Stiffness in Fabrics

A number of other test methods have been used to help determine flexural cycle properties in materials. This testing type typically involves putting materials through thousands of rapidly performed bending cycles to determine the material’s resistance to high volumes of rapid flexing. The material is then tested for microscopic surface cracking. Different polymer types and geomembrane formulations, including reinforced and non-reinforced, as well as material thickness, will demonstrate various levels of cycle performance. It should be noted that most of these test methods were designed for upholstery, leather, clothing, and wire coatings, not geomembranes. Adapting these test methods to geomembranes will require further industry research and testing to determine the suitability based on the different geomembrane polymers, types, and thicknesses. In actual applications, geomembranes with proper subgrade designs will not require significant multiaxial performance properties. Properly designed and tensioned floating covers are typically subjected to limited flexural cycles during their lifetime, usually less than a few thousand cycles associated with changes in water levels. Below are three ASTM test methods to be used for material cycle testing.

- ASTM D6182-00 (2015) – Standard test method for flexibility and adhesion of finish on leather

- ISO 7854:1995 – Rubber- or plastics-coated fabrics — Determination of resistance to damage by flexing

- ASTM D2097 – Standard Test Method for Flex Testing of Finish on Upholstery Leather

Summary

Flexibility is an important performance property of geomembranes. It is an important property when prefabricating liners and for applications where the liner will be folded or strained. Strain can be the result of thermal expansion and contraction in exposed geomembrane applications, inadequate subgrade conditions, or gases trapped under the liner. Flexibility varies by material type and the geomembrane’s structure, whether reinforced or non-reinforced. While certain geomembrane types, including PVC, PVC-EIA (Ethylene Interpolymer Alloy), fRPP, and EPDM, are noted to have very good flexibility, there can be performance tradeoffs with these materials, including chemical resistance and UV properties unless specially formulated. Contact Layfield Geosynthetics for further information on geomembrane flexibility and geomembrane selection.

References

- Assessment of Maximum Allowable Strains in Polyethylene and Polypropylene Geomembranes – Ian Peggs, Bruch Schmucker and Peter Carey

- A Guide to Polymeric Geomembranes, A Practical Approach, John Scheirs, ExcelPlas

- Fabricated Geomembrane Institute (FGI) https://www.fabricatedgeomembrane.com/

Related Articles

View All News